Smart Manufacturing and Logistics

AI Factory (FactoryOne)

Transform your manufacturing facilities into a digitalized and

intelligent AI factory that enables the efficient management of

production, quality, and facilities based on AI and big data.

Based on our experience of building multiple AI factories, we provide a comprehensive AI factory service that integrates IT solutions with facility automation.

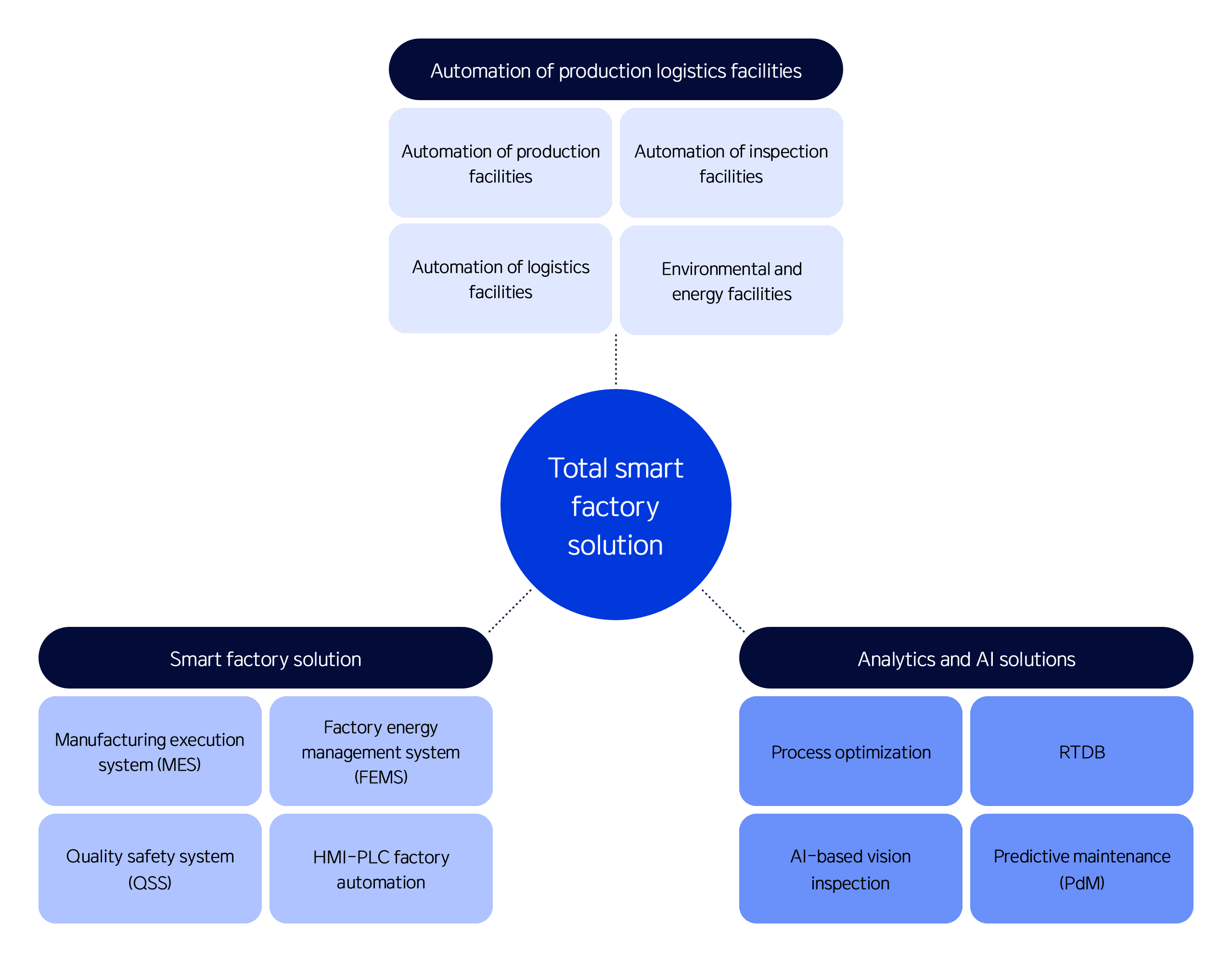

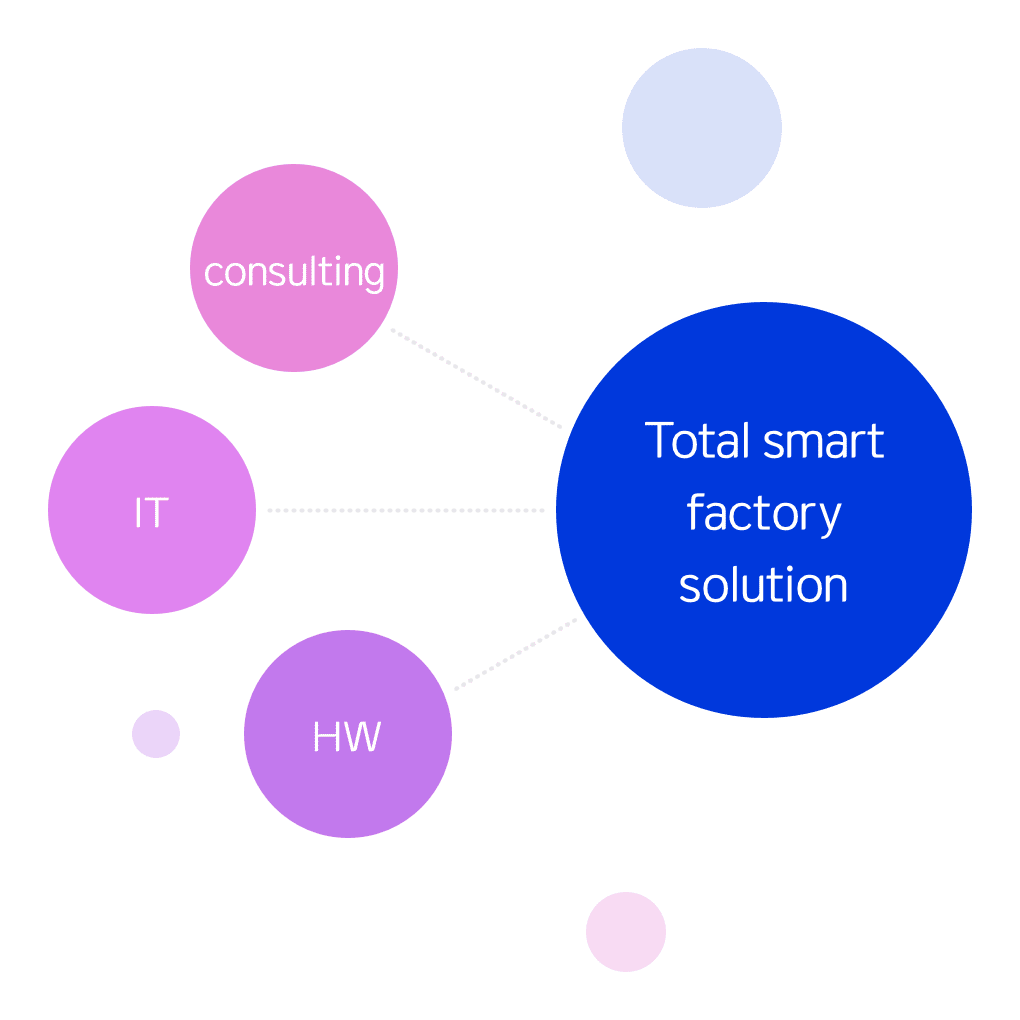

Total smart factory solution

- Automation of production logistics facilities

- Automation of production facilities

- Automation of inspection facilities

- Automation of logistics facilities

- Environmental and energy facilities

- Smart factory solution

- Manufacturing execution system(MES)

- Factory energy management system(FEMS)

- Quality safety system(QSS)

- HMI-PLC factory automation

- Analytics and AI solutions

- Process optimization

- RTDB

- AI-based vision inspection

- Predictive maintenance(PdM)

-

TURN-KEY SERVICE

- Comprehensive consulting and design for smart factories

- Installation and commissioning of production and logistics facilities

- Design and manufacture of production and logistics facilities

- Construction and stabilization of IT systems

- Design and development of IT systems

- Management and maintenance of smart factories

-

Smart factory consulting

- Consulting on process improvement

- Factory energy efficiency

- Factory layout design

- IT consulting

- Consulting on factory automation

- Consulting on system integration

- Consulting on factory automation

- Factory management and maintenance

The service is recommended for

Service Achievements

-

Productivity

0%

Productivity is greatly enhanced through the automation of production facilities and the efficient management of on-site inventory, production order, and performance with the manufacturing execution system (MES).

-

Promptness

0%

Digital transformation of production and utility facilities enables prompt response to anomalies through early detection and AI-based prediction.

-

Quality assurance

0%

Key factors of product quality such as GMPs and CCPs are monitored, and quality defects are predicted in advance through AI-based data prediction and vision inspection.

Main Services

Automated production and logistics facilities

We provide a total service for the automation of facilities in all areas of production for the construction of an optimized smart factory.

-

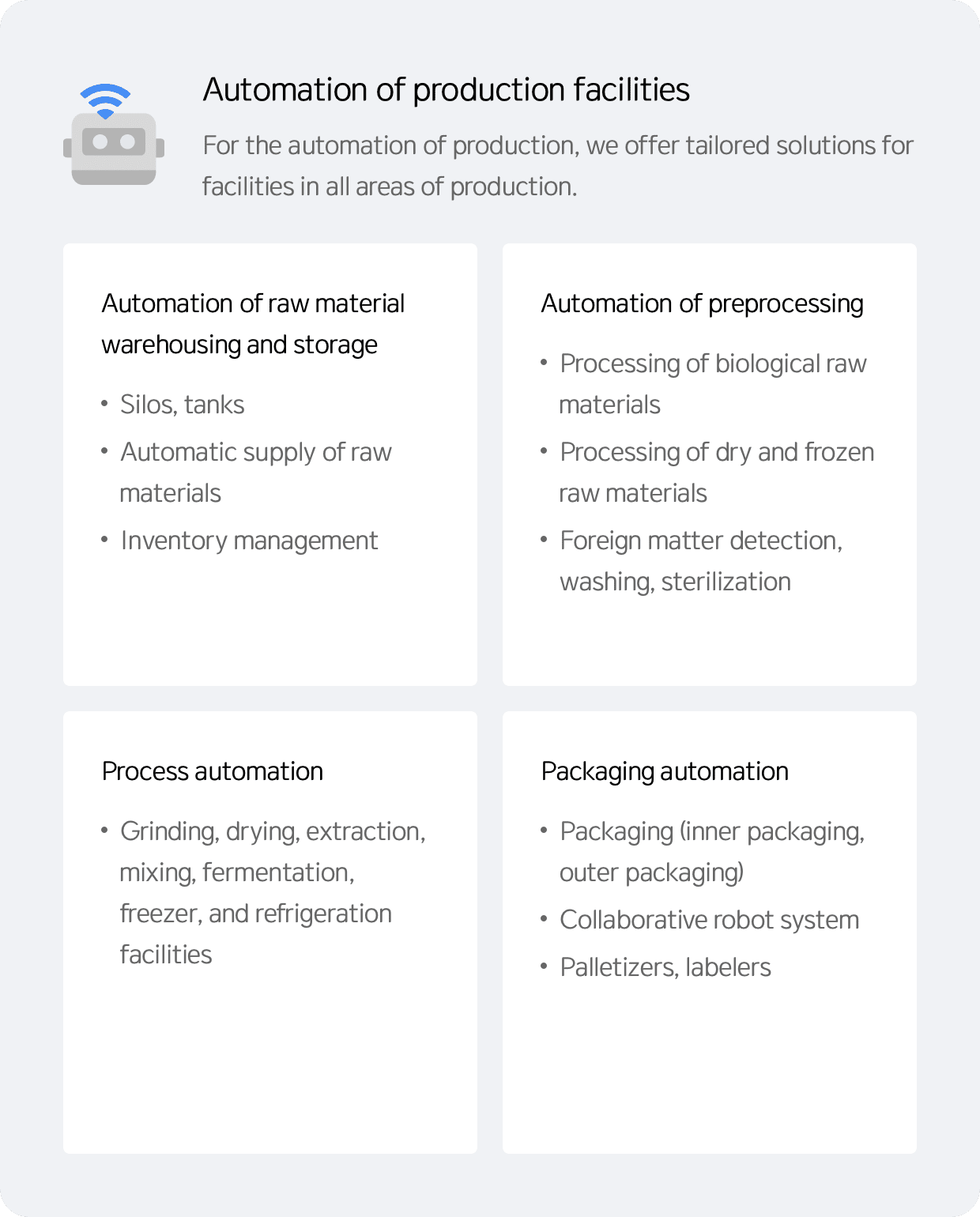

Automation of production facilities

For the automation of production, we offer tailored solutions for facilities in all areas of production.

- Automation of raw material warehousing and storage

- Silos, tanks

- Automatic supply of raw materials

- Inventory management

- Automation of preprocessing

- Processing of biological raw materials

- Processing of dry and frozen raw materials

- Foreign matter detection, washing, sterilization

- Process automation

- Grinding, drying, extraction, mixing, fermentation, freezer, and refrigeration facilities

- Packaging automation

- Packaging (inner packaging, outer packaging)

- Collaborative robot system

- Palletizers, labelers

-

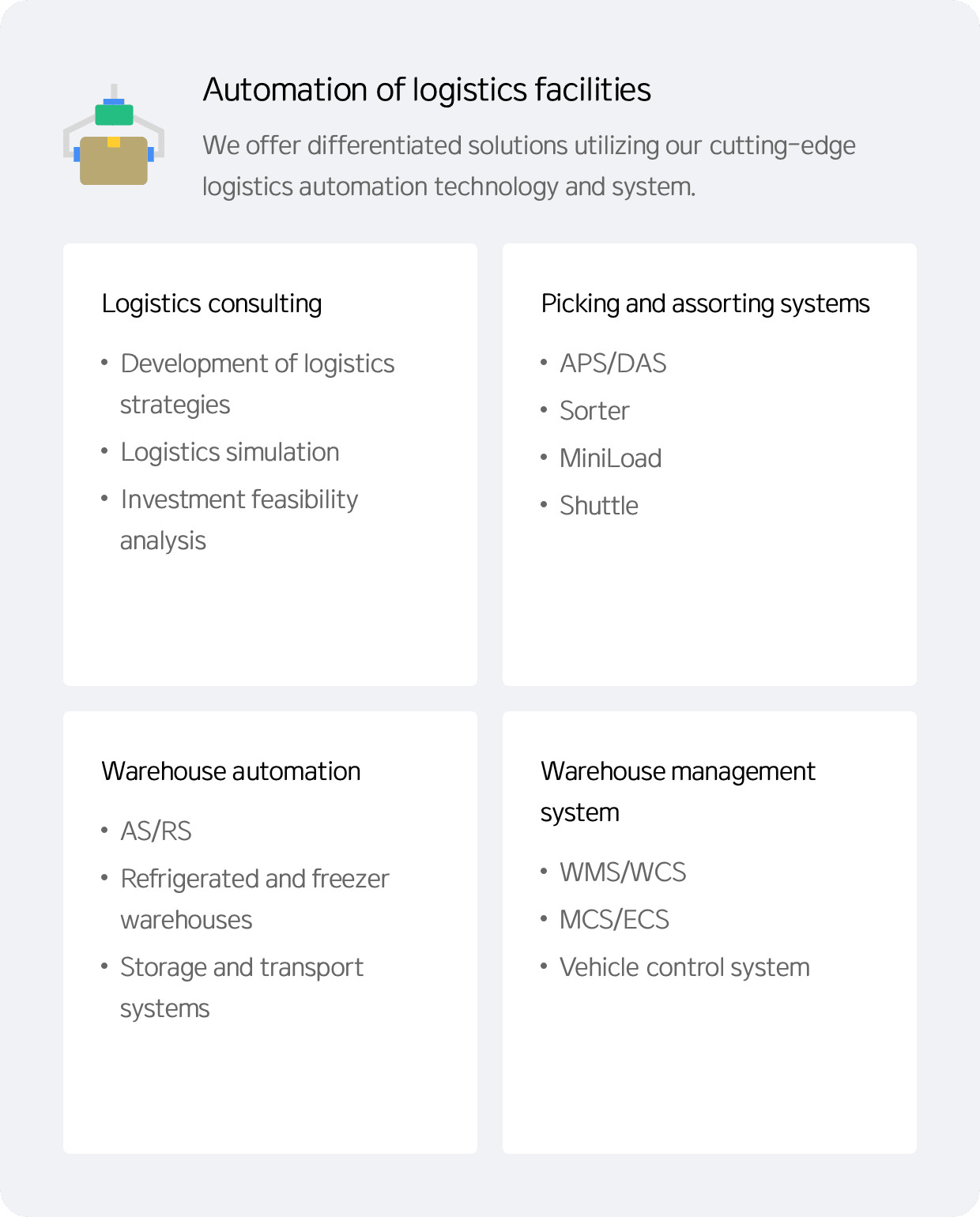

Automation of logistics facilities

We offer differentiated solutions utilizing our cutting-edge logistics automation technology and system.

- Logistics consulting

- Development of logistics strategies

- Logistics simulation

- Investment feasibility analysis

- Picking and assorting systems

- APS/DAS

- MiniLoad

- Sorter

- Shuttle

- Warehouse automation

- AS/RS

- Refrigerated and freezer warehouses

- Storage and transport systems

- Warehouse management system

- WMS/WCS

- MCS/ECS

- Vehicle control system

-

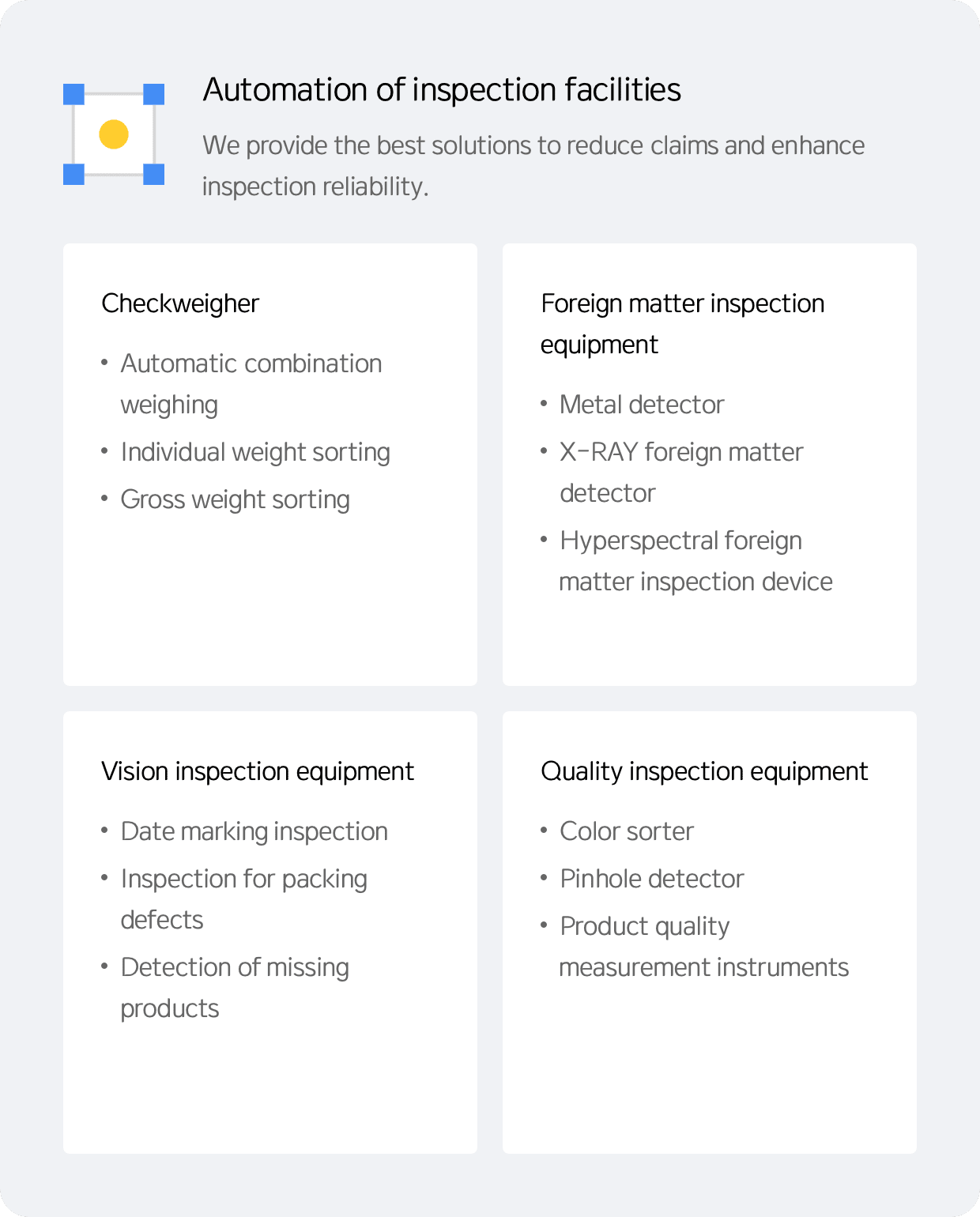

Automation of inspection facilities

We provide the best solutions to reduce claims and enhance inspection reliability.

- Checkweigher

- Automatic combination weighing

- Individual weight sorting

- Gross weight sorting

- Foreign matter inspection equipment

- Metal detector

- X-RAY foreign matter detector

- Hyperspectral foreign matter inspection device

- Vision inspection equipment

- Date marking inspection

- Inspection for packing defects

- Detection of missing products

- Quality inspection equipment

- Color sorter

- Pinhole detector

- Product quality measurement instruments

-

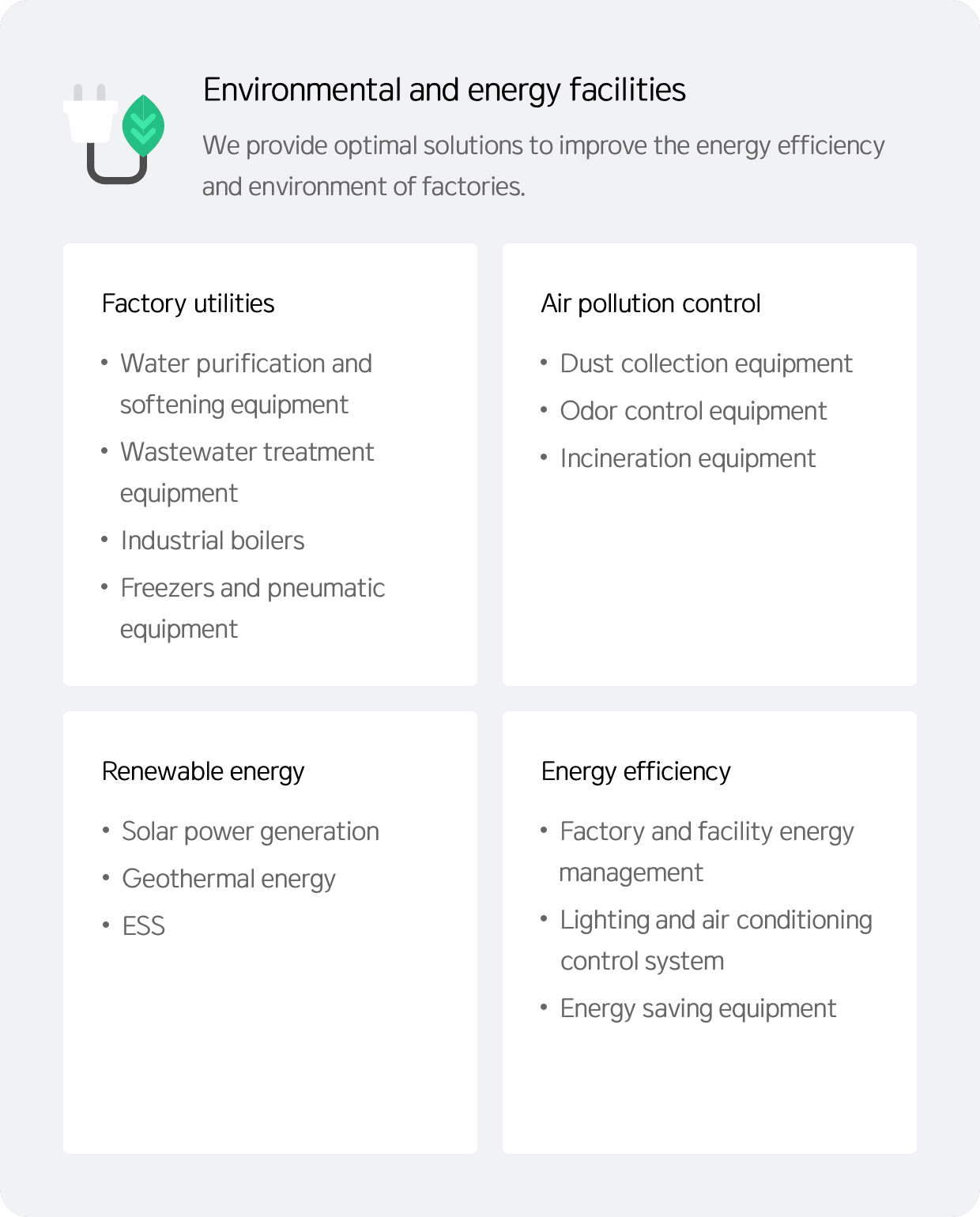

Environmental and energy facilities

We provide optimal solutions to improve the energy efficiency and environment of factories.

- Factory utilities

- Water purification and softening equipment

- Wastewater treatment equipment

- Industrial boilers

- Freezers and pneumatic equipment

- Air pollution control

- Dust collection equipment

- Odor control equipment

- Incineration equipment

- Renewable energy

- Solar power generation

- Geothermal energy

- ESS

- Energy efficiency

- Factory and facility energy management

- Lighting and air conditioning control system

- Energy saving equipment

AI Factory solution FactoryOne

An integrated solution that provides various services for building a smart factory

FactoryOne

-

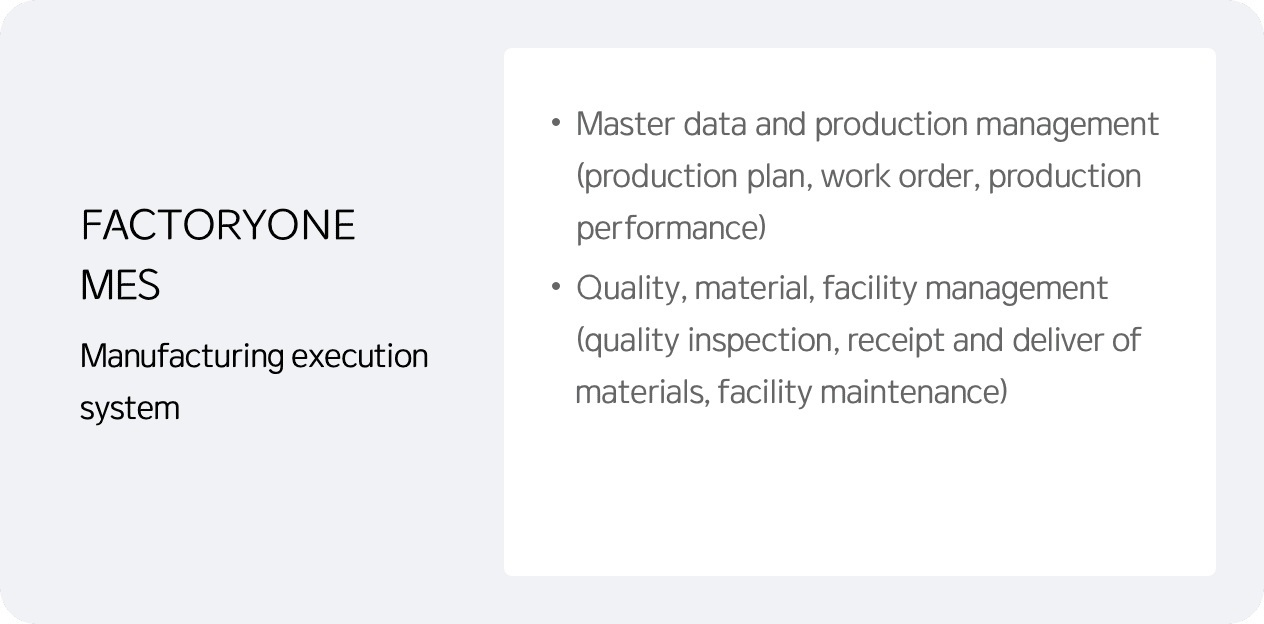

- FACTORYONE MES Manufacturing execution system

- Master data and production management (production plan, work order, production performance)

- Quality, material, facility management (quality inspection, receipt and deliver of materials, facility maintenance)

-

- FACTORYONE BOARD Production monitoring and dashboards

- Production monitoring (facility operation status, production status)

- Real-time monitoring and status of production KPIs

-

- FACTORYONE QSS Quality safety system

- Support for Smart HACCP and GMP certification

- Real-time management of CCPs, history inquiry, data storage and analysis

- Management of data on overall quality, including data on quality tracing, checkweighing and data marking inspection

-

- FACTORYONE MMS Facility management system

- Management of facility maintenance schedules, analysis of overall equipment effectiveness (OEE)

- Equipment failure history management, predictive maintenance and real-time management of equipment alarms

-

- FACTORYONE FEMS Factory energy management system

- Real-time energy monitoring (energy target and usage management)

- Analysis of energy consumption data and improvement of energy efficiency

- Management of legal regulatory indicators (automatic calculation and management of carbon emissions)

-

- FACTORYONE FAI Factory automation interface

- PLC/HMI: production operating conditions, facility information, alarm linkage

- On-site equipment: barcode scanner, computer, and inspection equipment connection

-

- FACTORYONE MOBILE Mobile factory management system

- Mobile daily process report (production, quality, maintenance)

- Mobile facility management (facility alarms, drawings, maintenance measures)

Analytics and AI solutions

We provide advanced production management solutions required at manufacturing sites with our latest proprietary AI technology.

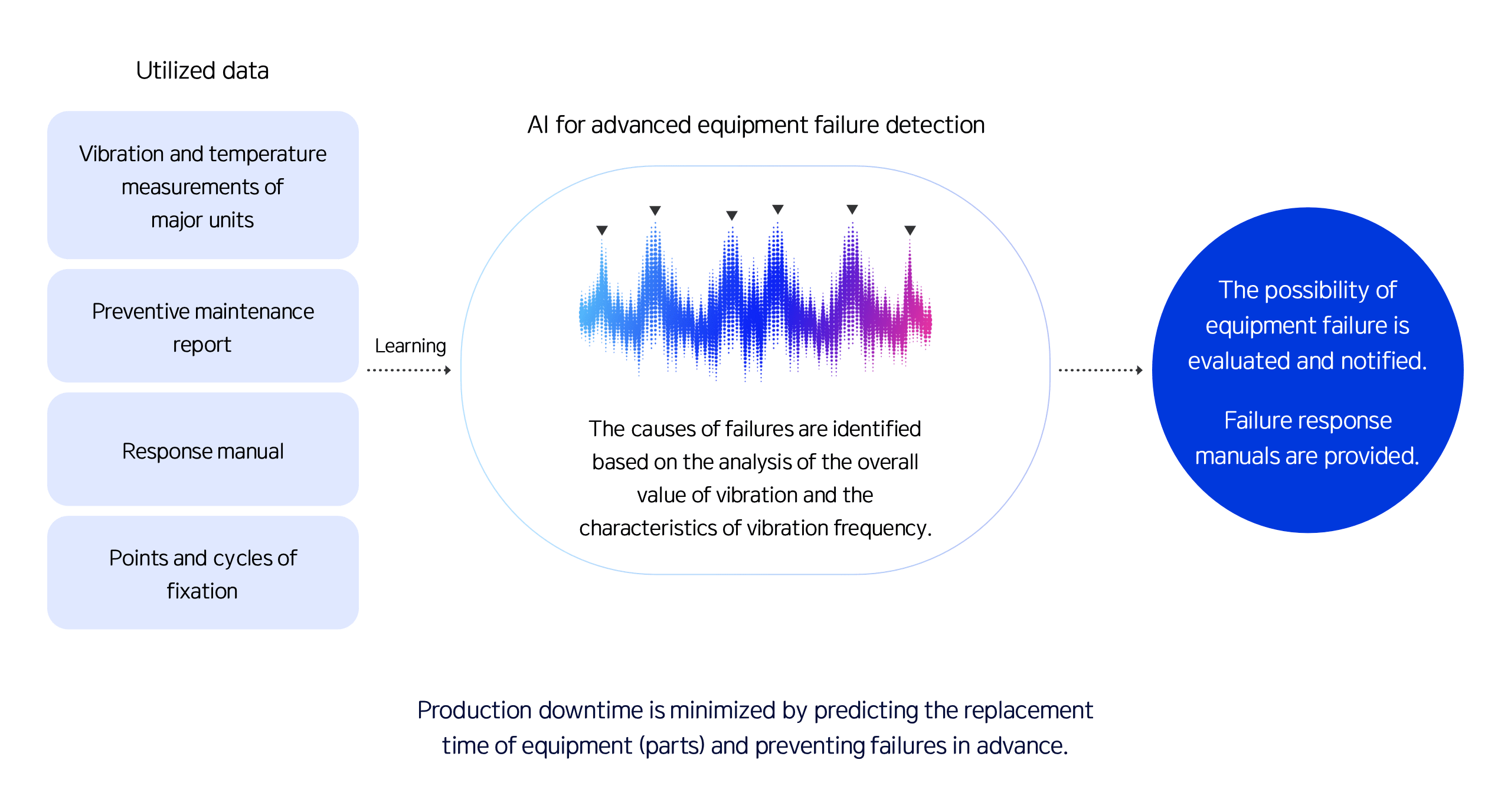

AI-based predictive maintenance

Based on the analysis of failure types and patterns by equipment unit using AI, the timings of future failures are predicted, and response manuals for each failure type are provided to minimize failures and equipment downtime, thereby maximizing productivity.

-

- Utilized data

- Vibration and temperature measurements of major units

- Preventive maintenance report

- Response manual

- Points and cycles of fixation

- Learning

-

- AI for advanced equipment failure detection

- The causes of failures are identified based on the analysis of the overall value of vibration and the characteristics of vibration frequency.

- The possibility of equipment failure is evaluated and notified. Failure response manuals are provided.

Production downtime is minimized by predicting the replacement time of equipment (parts) and preventing failures in advance.

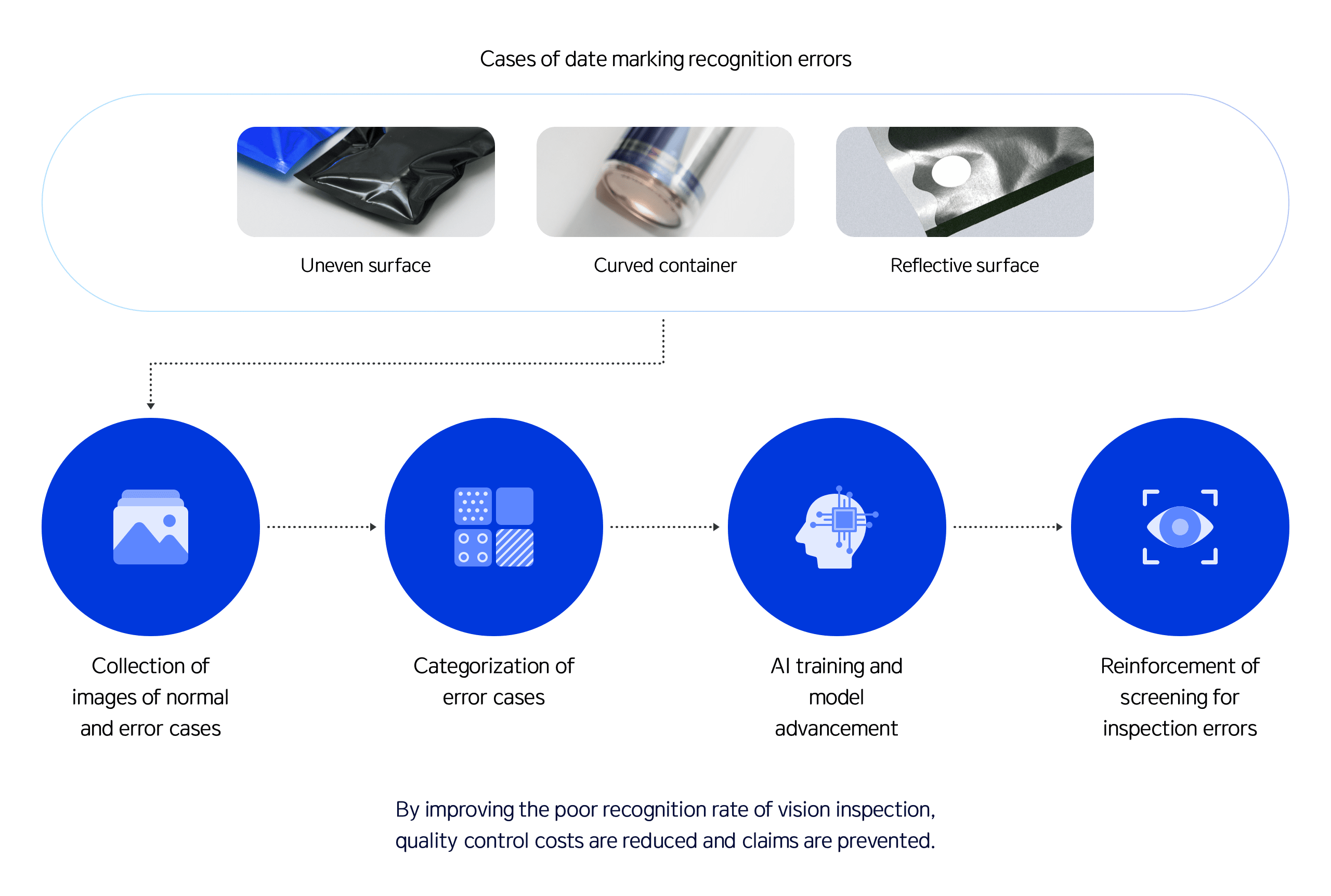

AI-based vision inspection

AI-based vision inspection helps various environments without reliable inspection and sorting systems to improve the recognition rate of vision inspection to prevent claims and improve customer confidence in product quality.

Cases of date marking recognition errors

-

- Uneven surface

- Curved container

- Reflective surface

-

- Collection of images of normal and error cases

- Categorization of error cases

- AI training and model advancement

- Reinforcement of screening for inspection errors

By improving the poor recognition rate of vision inspection, quality control costs are reduced and claims are prevented.

Differentiated Features

-

All-in-one solution for building an AI factory

A comprehensive service is provided for building a smart factory for food and pharmaceutical businesses, including consulting, detailed design, construction, facility and solution supply, and maintenance.

-

Real-time data collection and optimal algorithms

Data on production, utility, and energy facilities is collected in real time, and algorithms for integrated data utilization and analysis are provided to improve processes and maximize facility efficiency.

-

Creation of a smart factory through IT-OT-HW integration

By linking IT solutions, controls, and facilities in real time, an AI smart factory is created, which goes beyond the mere idea of factory automation, enabling real-time management of production sites and optimized operation of processes.

Customer Cases

Find related

news here.

Would you like

to inquire now?

Please submit your inquiry,

and we will respond as soon as possible.

No attachment found

* You can send up to 10 MB in attachments. Supported file formats: zip, pdf, hwp, ppt, pptx, doc, docx, xls, xlsx, jpg, jpeg, png, gif

1. Purpose: Provision of responses for customer inquiries and management of inquiry status

2. Collection Items: Name, contact information, e-mail address, company

3. Retention Period: For 36 months from the date on which the consent is given

You have the right to refuse to provide consent to the collection and use of your personal information. However, please note that if you fail to provide consent, the submission of your inquiry will be restricted.

※ CJ OliveNetworks does not collect the personal information of a minor under the age of 14.